Valve leakage detection

-

Basic principles

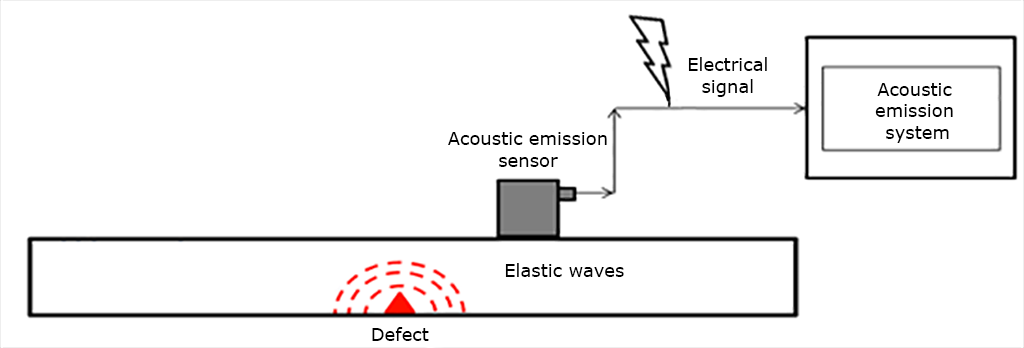

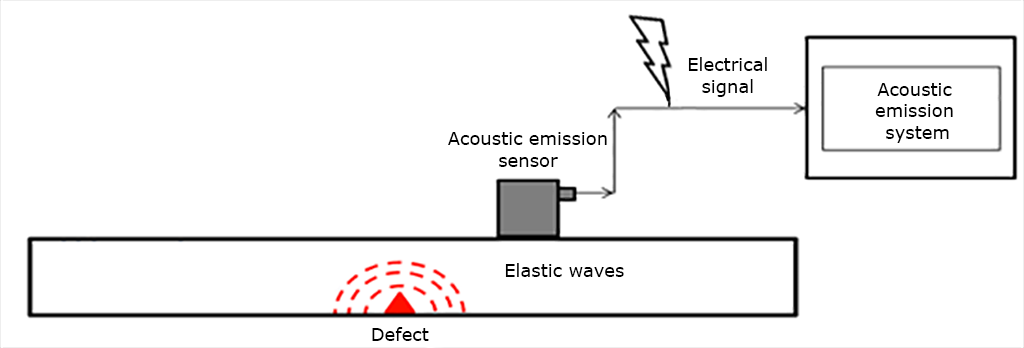

Acoustic emission is an effective method of nondestructive testing based on the registration of elastic vibrations (acoustic waves) generated during various processes occurring in the monitoring object, such as deformation of stressed material, outflow of gases, liquids, crystallization of the material and others.

Acoustic waves propagate from the source to acoustic emission sensors, where they are converted into electrical signals arriving at the AE system for further processing and analysis. The analysis of acoustic emission data allows to determine the location of a defect, gives an information of its nature and the degree of danger.

Application area:

The acoustic emission method is effectively used in the oil and gas and chemical industries, thermal and nuclear power engineering, construction, metallurgy, and many others.

The advantages of the method:

- The method makes it possible to monitor a wide variety of technological processes, as well as processes associated with changing the properties, structure and state of the object.

- The area of testing by the method of acoustic emission is much larger than that of other methods of nondestructive testing. The maximum effectiveness of the method is achieved when testing large and long objects, such as pipelines, tanks and building structures. For example, an efficient tested area for a gas pipeline in one measurement cycle with a AE system can reach 8 km.

- The method has significantly less restrictions related to the properties and structure of the object compared to other methods of NDT.

- High sensitivity of the method to growing and developing defects allows to identify them at an early stage, to assess the degree of danger and the rate of their development.

-

Practical recommendations

1. When using the acoustic emission method, it should be remembered that each tested object has its own unique properties. To ensure greater reliability of the data obtained at the testing at each site, it is necessary to carry out measurements of the propagation velocity of waves, the attenuation coefficient, and take into account other properties characteristic of the object.

2. Selecting a frequency filter is one of the most important decisions when setting up an acoustic emission system. Filters used in systems:

- 30 - 500 kHz - universal for all tasks;

- 30 - 100 kHz - for leak monitoring;

- 100 - 300 (400) kHz - for testing welded joints and the base metal of steel structures.

3. Selection of time parameters

- Hit definition time SCETO:

- 500 μs for vessels and tank walls;

- 1000 μs - for process pipelines;

- 2000 μs - for main pipelines;

- Dead Time - half of SCETO.

- Max. Duration is always 65535 μs.

4. An important parameter when tuning in an object is the propagation velocity of waves in the object. The velocity depends on the material of the object, its filling, insulation, thickness, type of AE sensor, operating frequency band, threshold, distance between the sensors, etc. When monitoring and adjusting the location, it is very important to make preliminary measurements of the wave propagation velocity. This operation is provided by the software and can be read in detail in the manual. In practice, the following approximate velocity values are obtained:

- about 3000 m / s for vessels and pipelines with gas;

- about 5000 m / s for vessels and pipelines with liquid for a wave in a wall less than 50 mm thick;

- about 2900 m / s for vessels and pipelines with liquid for a wave in a wall thicker than 50 mm;

- about 1400 m / s for a wave of water in the pipeline;

- about 1200 m / s for a wave of oil in the pipeline.

- Examples of application

Acoustic emission is an effective method of nondestructive testing based on the registration of elastic vibrations (acoustic waves) generated during various processes occurring in the monitoring object, such as deformation of stressed material, outflow of gases, liquids, crystallization of the material and others.

Acoustic waves propagate from the source to acoustic emission sensors, where they are converted into electrical signals arriving at the AE system for further processing and analysis. The analysis of acoustic emission data allows to determine the location of a defect, gives an information of its nature and the degree of danger.

Application area:

The acoustic emission method is effectively used in the oil and gas and chemical industries, thermal and nuclear power engineering, construction, metallurgy, and many others.

The advantages of the method:

- The method makes it possible to monitor a wide variety of technological processes, as well as processes associated with changing the properties, structure and state of the object.

- The area of testing by the method of acoustic emission is much larger than that of other methods of nondestructive testing. The maximum effectiveness of the method is achieved when testing large and long objects, such as pipelines, tanks and building structures. For example, an efficient tested area for a gas pipeline in one measurement cycle with a AE system can reach 8 km.

- The method has significantly less restrictions related to the properties and structure of the object compared to other methods of NDT.

- High sensitivity of the method to growing and developing defects allows to identify them at an early stage, to assess the degree of danger and the rate of their development.

1. When using the acoustic emission method, it should be remembered that each tested object has its own unique properties. To ensure greater reliability of the data obtained at the testing at each site, it is necessary to carry out measurements of the propagation velocity of waves, the attenuation coefficient, and take into account other properties characteristic of the object.

2. Selecting a frequency filter is one of the most important decisions when setting up an acoustic emission system. Filters used in systems:

- 30 - 500 kHz - universal for all tasks;

- 30 - 100 kHz - for leak monitoring;

- 100 - 300 (400) kHz - for testing welded joints and the base metal of steel structures.

3. Selection of time parameters

- Hit definition time SCETO:

- 500 μs for vessels and tank walls;

- 1000 μs - for process pipelines;

- 2000 μs - for main pipelines;

- Dead Time - half of SCETO.

- Max. Duration is always 65535 μs.

4. An important parameter when tuning in an object is the propagation velocity of waves in the object. The velocity depends on the material of the object, its filling, insulation, thickness, type of AE sensor, operating frequency band, threshold, distance between the sensors, etc. When monitoring and adjusting the location, it is very important to make preliminary measurements of the wave propagation velocity. This operation is provided by the software and can be read in detail in the manual. In practice, the following approximate velocity values are obtained:

- about 3000 m / s for vessels and pipelines with gas;

- about 5000 m / s for vessels and pipelines with liquid for a wave in a wall less than 50 mm thick;

- about 2900 m / s for vessels and pipelines with liquid for a wave in a wall thicker than 50 mm;

- about 1400 m / s for a wave of water in the pipeline;

- about 1200 m / s for a wave of oil in the pipeline.