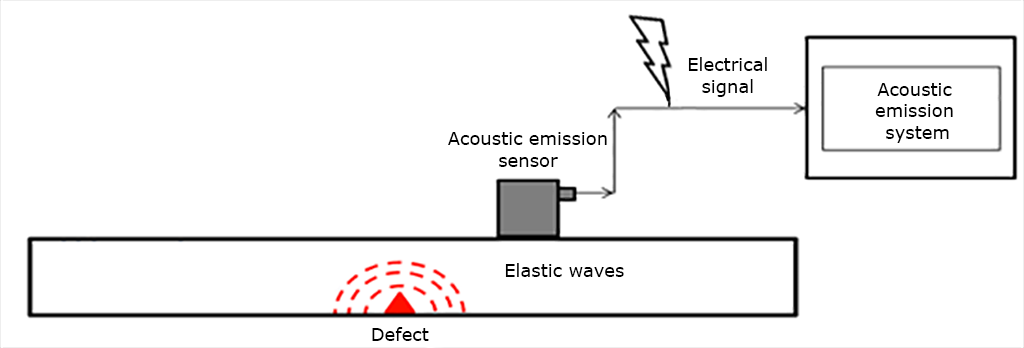

Acoustic emission is an effective method of nondestructive testing based on the registration of elastic vibrations (acoustic waves) generated during various processes occurring in the monitoring object, such as deformation of stressed material, outflow of gases, liquids, crystallization of the material and others.

Acoustic waves propagate from the source to acoustic emission sensors, where they are converted into electrical signals arriving at the AE system for further processing and analysis. The analysis of acoustic emission data allows to determine the location of a defect, gives an information of its nature and the degree of danger.

Application area:

The acoustic emission method is effectively used in the oil and gas and chemical industries, thermal and nuclear power engineering, construction, metallurgy, and many others.

The advantages of the method:

- The method makes it possible to monitor a wide variety of technological processes, as well as processes associated with changing the properties, structure and state of the object.

- The area of testing by the method of acoustic emission is much larger than that of other methods of nondestructive testing. The maximum effectiveness of the method is achieved when testing large and long objects, such as pipelines, tanks and building structures. For example, an efficient tested area for a gas pipeline in one measurement cycle with a AE system can reach 8 km.

- The method has significantly less restrictions related to the properties and structure of the object compared to other methods of NDT.

- High sensitivity of the method to growing and developing defects allows to identify them at an early stage, to assess the degree of danger and the rate of their development.