-

Description

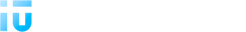

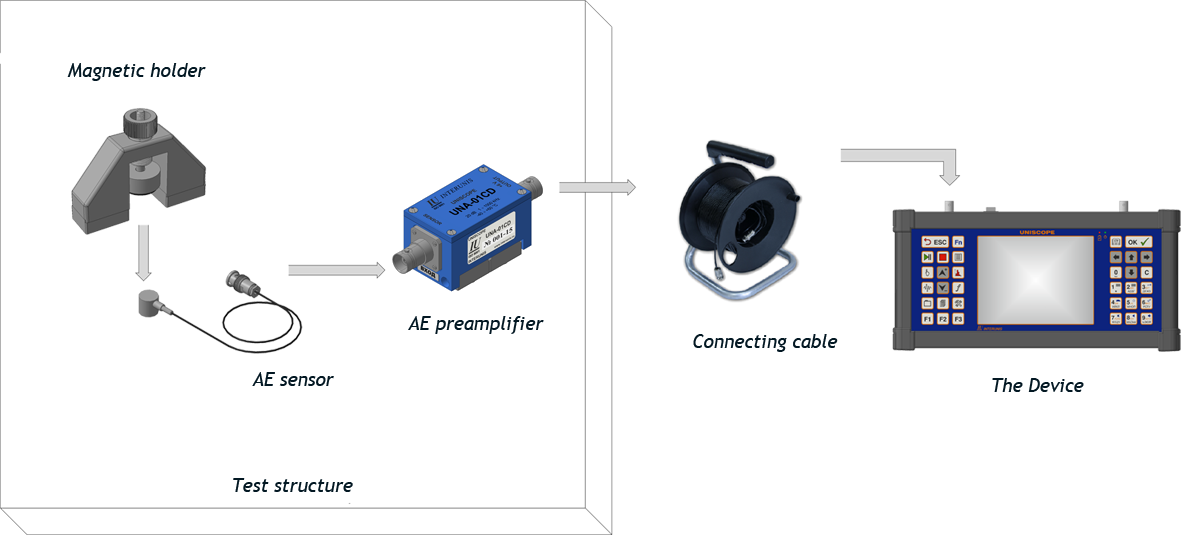

The universal NDT instrument outlined below, named «UNISCOPE», is the company’s state-of-the-art design, intended to satisfy the highest requirements of NDT experts. At present, on the basis of a single hardware platform the instrument incorporates the two-channel AE system with advanced features, the acoustic leak detector, the tensometer and the vibrometer. Furthermore, additional functions of «UNISCOPE» are under development, which in the long view will allow for using this device as an ultrasonic thickness meter, a generator of test electric and elastic impulses, an integrated thickness meter, a measuring instrument of electrochemical potentials and terrestrial currents, an eddy-current scanner and a magnetometer. Such universality is reached through using various external measuring units to be connected to the common computing device, provided with generic software with the modern friendly interface.

For information visualization, the device is equipped with a display protected with a transparent plate from mechanical and climatic impacts. Battery charging (p. 3, fig. 2) and electric supply state (p.4, fig. 2) LED indicators are located on the face side of the device. The electric supply switch (p. 3, fig. 1), two connectors for sources of analog systems (p.4a, 4b fig. 1), two connectors for external digital blocks (p. 6a, 6b fig. 1), as well as the section of interface connectors protected with a plug (p. 5, fig.1) are located on the side of the device containing, in particular, a connector for storage batteries charging.

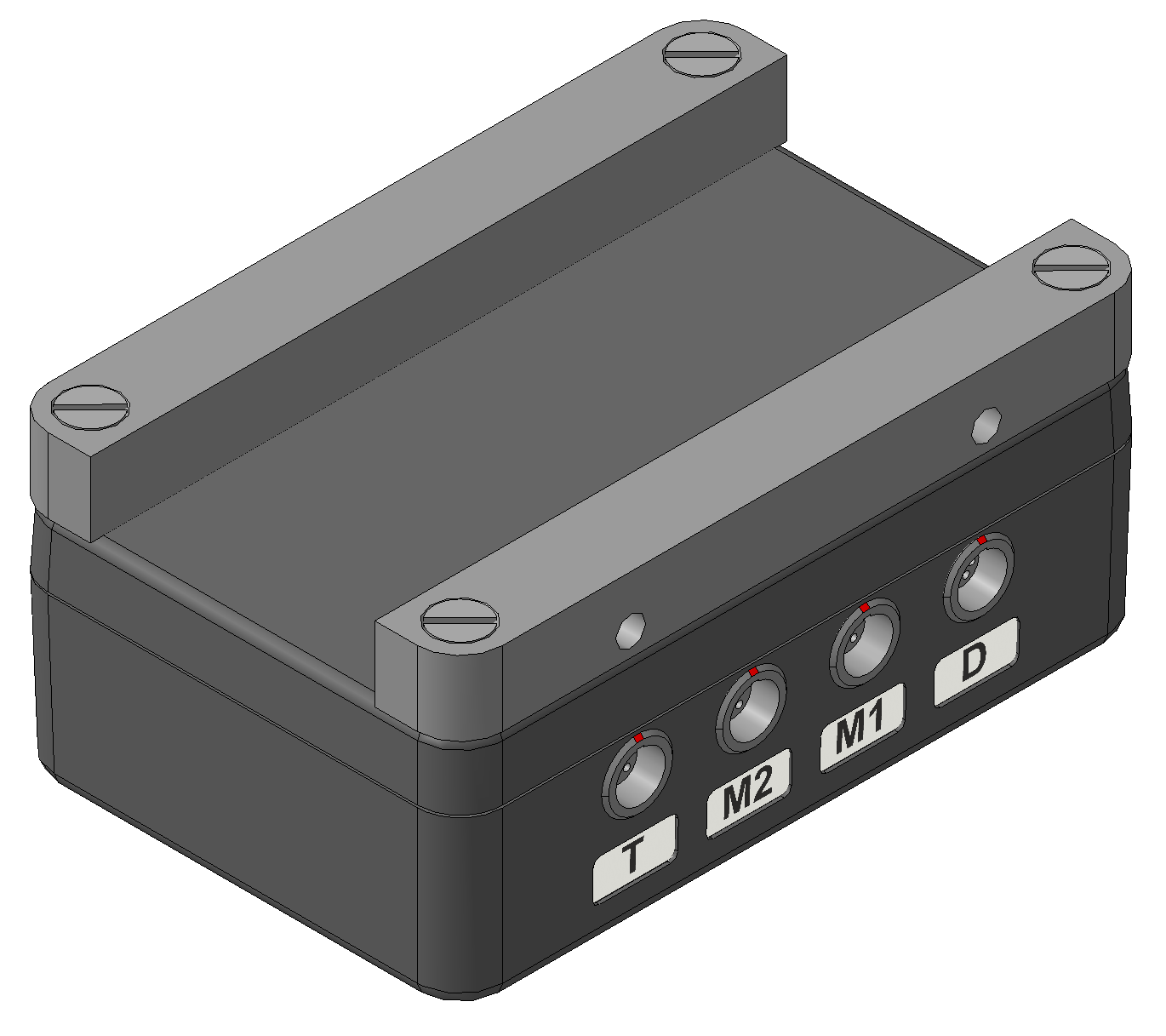

Fig. 1. Face panel (1 – panel of control push buttons; 2 –panel of adjustment push buttons; 3 – battery charging indicator; 4 – electric supply state indicator)

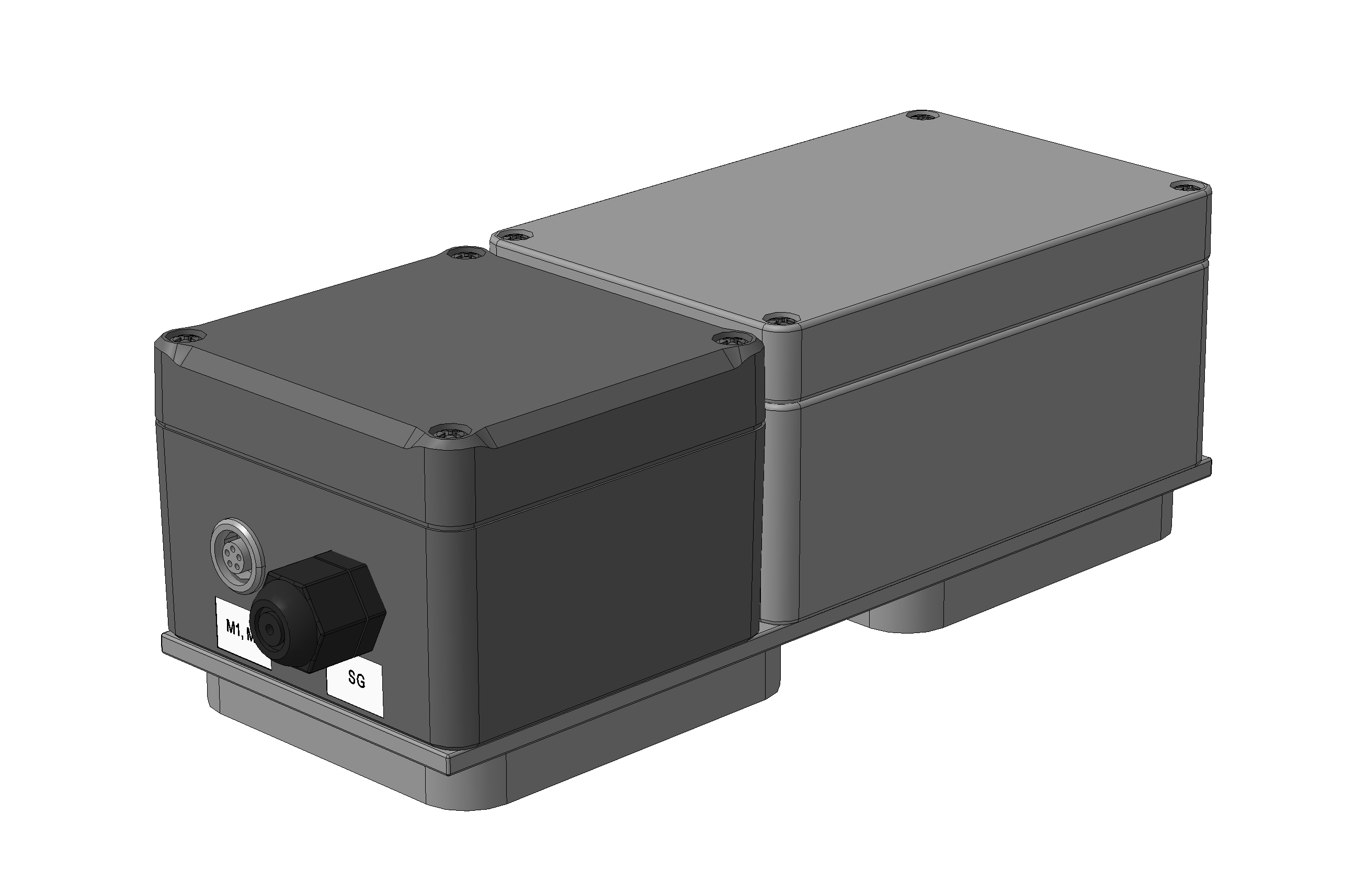

Fig. 2 General view of the device (1 – keyboard; 2 – display; 3 – ON/OFF push button; 4а – Channel No. 1 connector for registration of analog signals; 4b – Channel No. 2 connector for registration of analogue signals; 5 – plug of interface connectors section; 6а – digital channel No. 1 connector; 6b –digital channel No. 2 connector)

Distinctive peculiarities of «UNISCOPE»:

- small weight and optimal ergonomics for field operation;

- reliable protection from unfavourable external impacts;

- possible operation at negative temperatures;

- high modern level of hardware and software;

- two wide-band analog and two digital channels for connection of external measuring blocks;

- graphic image of results at the LCD display with light diode illumination;

- storage of big volumes of data at easily accessible information carriers;

- possible unification of two and more devices for multichannel measurements;

- prolonged operation from two built-in storage batteries.

Description of main operation modesIn the mode of AE measurements «UNISCOPE» is intended for nondestructive testing without decommission of industrial and technological pipelines, adapters and jumpers, gate valves and pressure regulators, vessels and cylinders, hoisting mechanisms and other industrial equipment along with possible linear localization and operative assessment of danger degree of AE sources.

Besides, in order to improve quality of useful signal separation at the background of various noises charge digital frequency filters and preliminary hardware filtration of input data by parameters of AE impulses are used. In parallel with AE registration by two analog channels parametric information can be recorded and by two digital channels in the single time scale for higher quality of the diagnostic information analysis.

In the leakage detection mode the «UNISCOPE» makes it possible to detect and quantitatively assess the values of gate valves leakages of various types and intention, working pressure and diameter for liquid and gaseous working environment. The leakage detection function is implemented on the basis of registration channels of AE impulses. The typical shape of leakage signals is identified by the system software. The value of medium consumption is evaluated on the basis of parameters of these signals. Depending on the type of the working medium, passage diameter and operating pressure of gate valves the average error of leakage may be equal from 0.1 to 20 l/min.

In the strain measurement mode the «UNISCOPE» is used for measuring the object nominal diameter in the real time scale. An important operation peculiarity in this mode is its possible use along with AE measurements for parametric testing accompaniment by means of observation of the changed value and loading character.

-

Composition

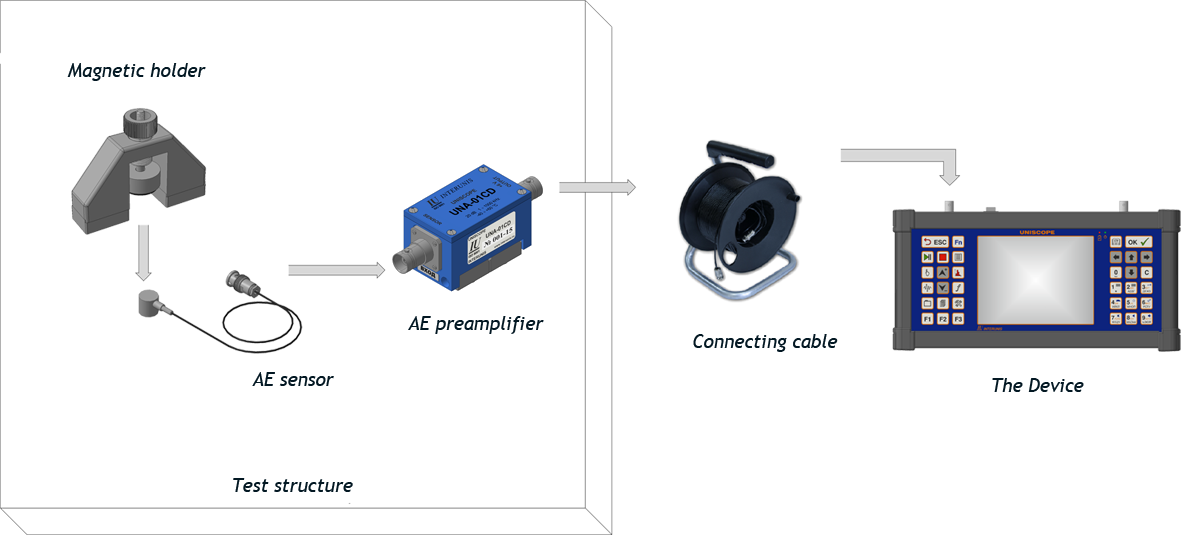

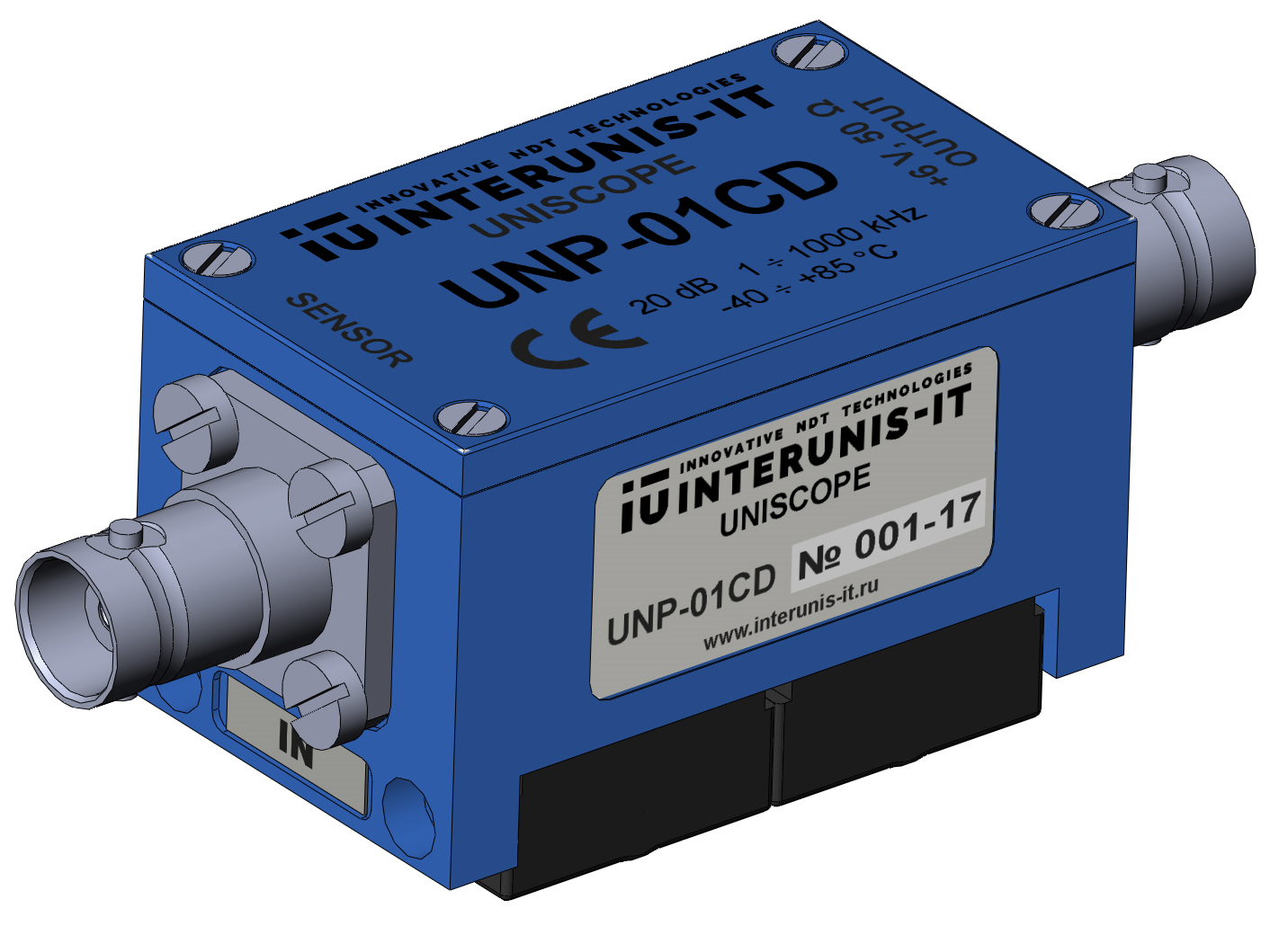

Unit «UNISCOPE» in Ex version and external matching unit «UNE-P» in Ex version have design implementing type of protection «n» (IEC 60079-15) and intrinsic safety «i» type for external circuits with level of protection «ia» (IEC 60079-11). Unit «UNISCOPE» in Ex version meets the requirements of IEC 60079-0. AE preamplifier «UNP» in Ex version is intrinsically safe (IEC 60079-11). Unit «UNISCOPE» in Ex version and connected devices can be located in hazardous areas according to their marking. Charger and interfaces connectors usage is forbidden in hazardous areas.

Explosion protection of AE preamplifier «UNP» in Ex version is provided by matching its intrinsically safe parameters with output intrinsically safe parameters of unit «UNISCOPE» in Ex version.

Accessories

Charger

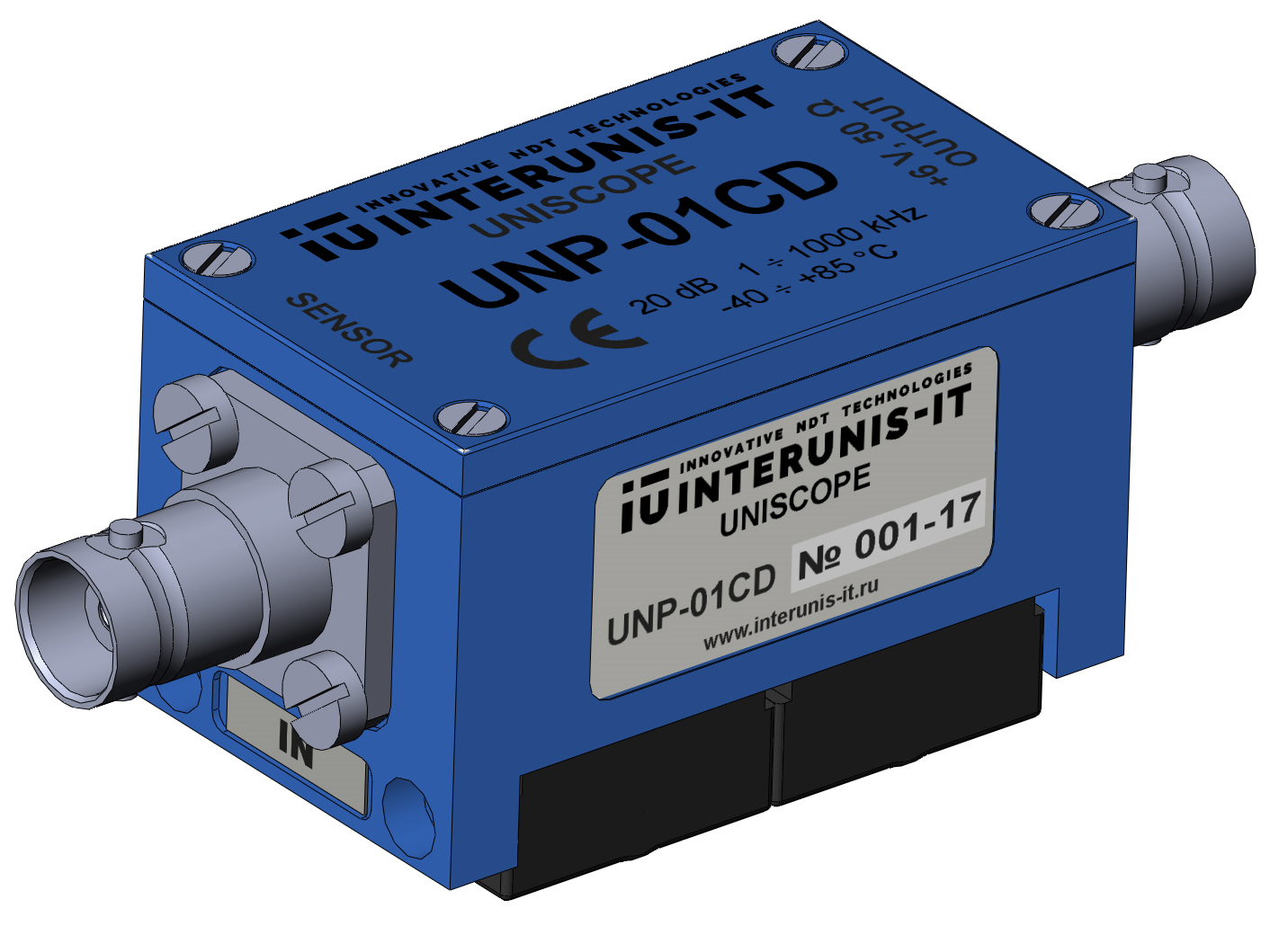

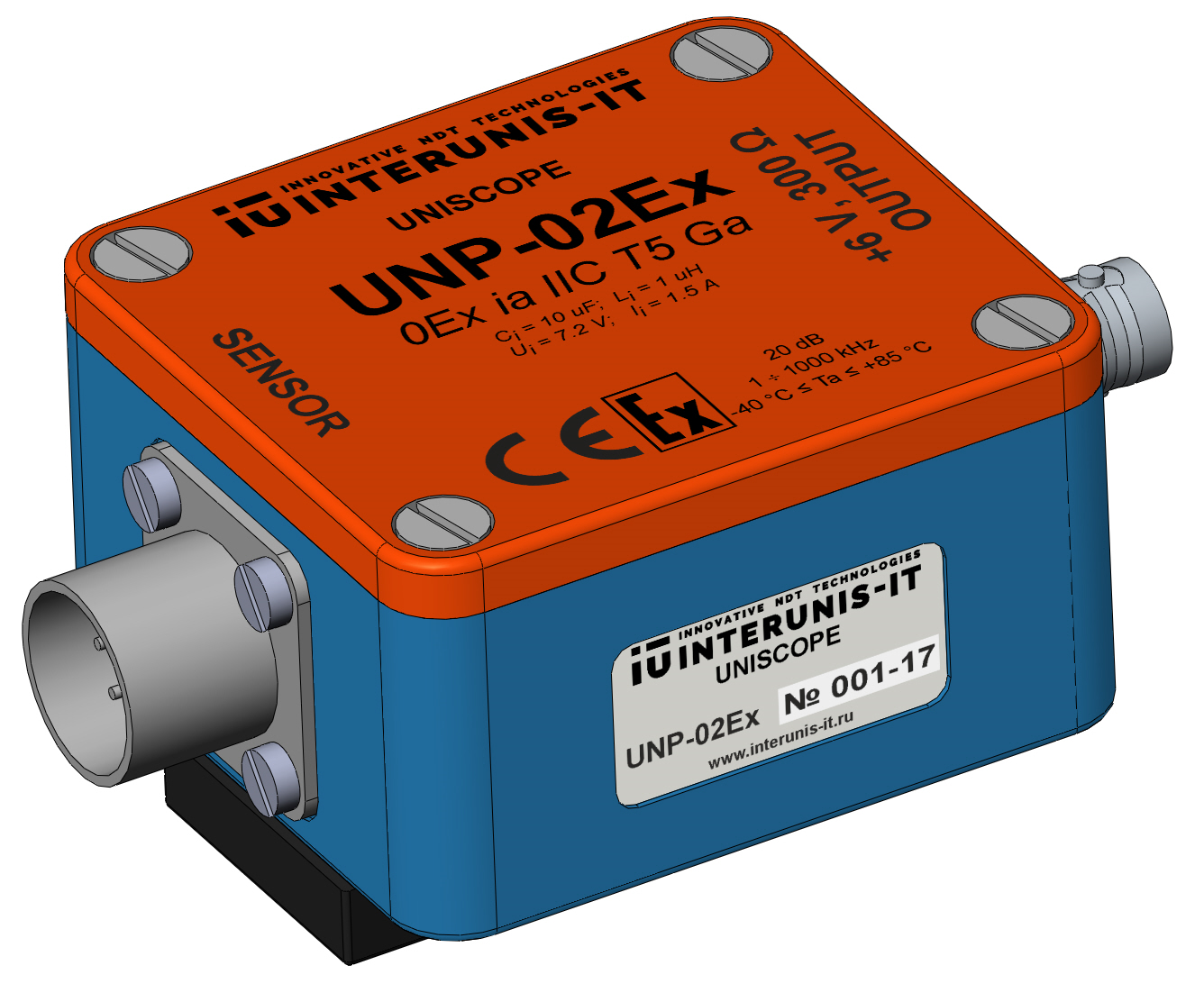

AE preamplifier «UNP»

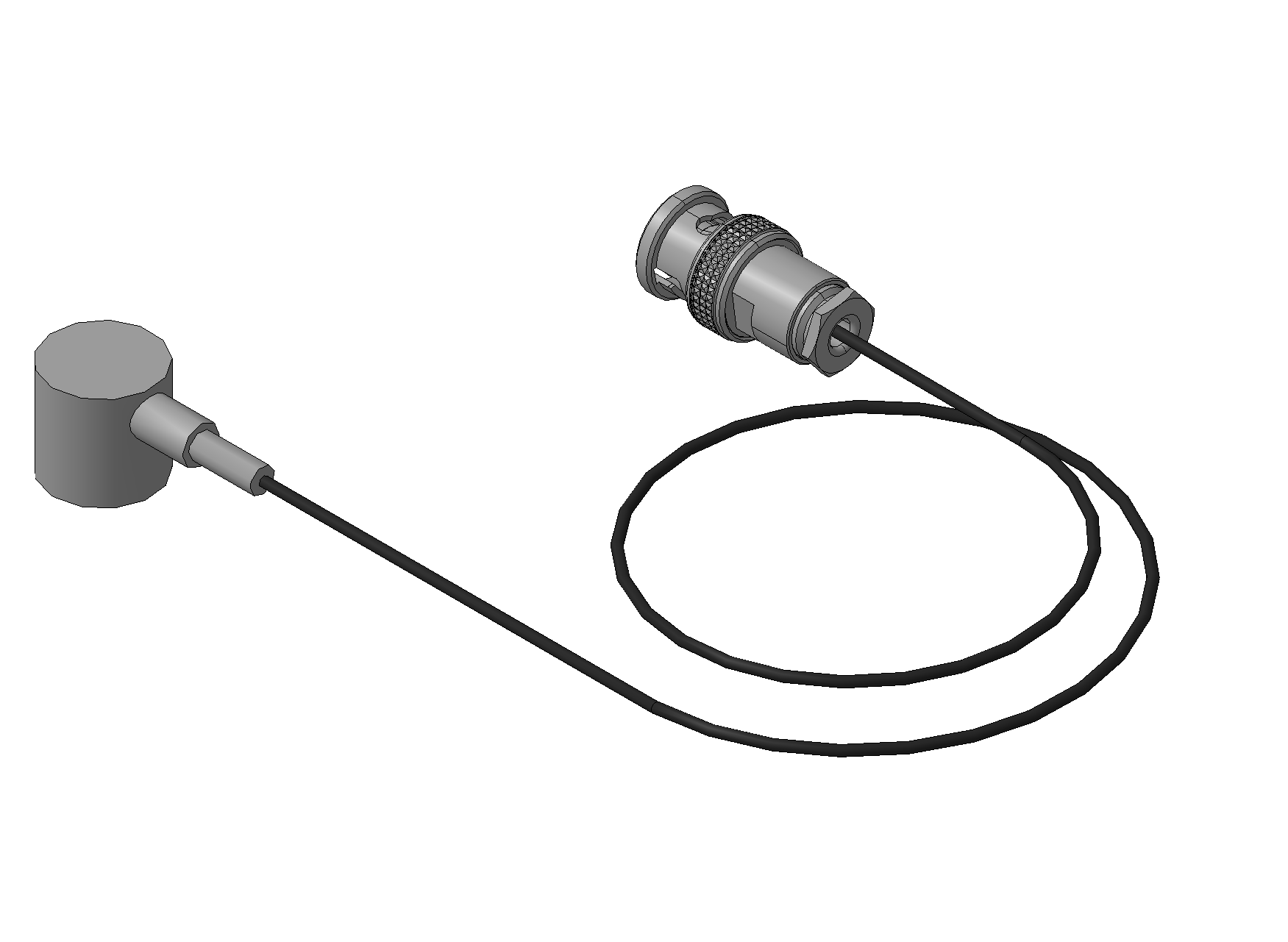

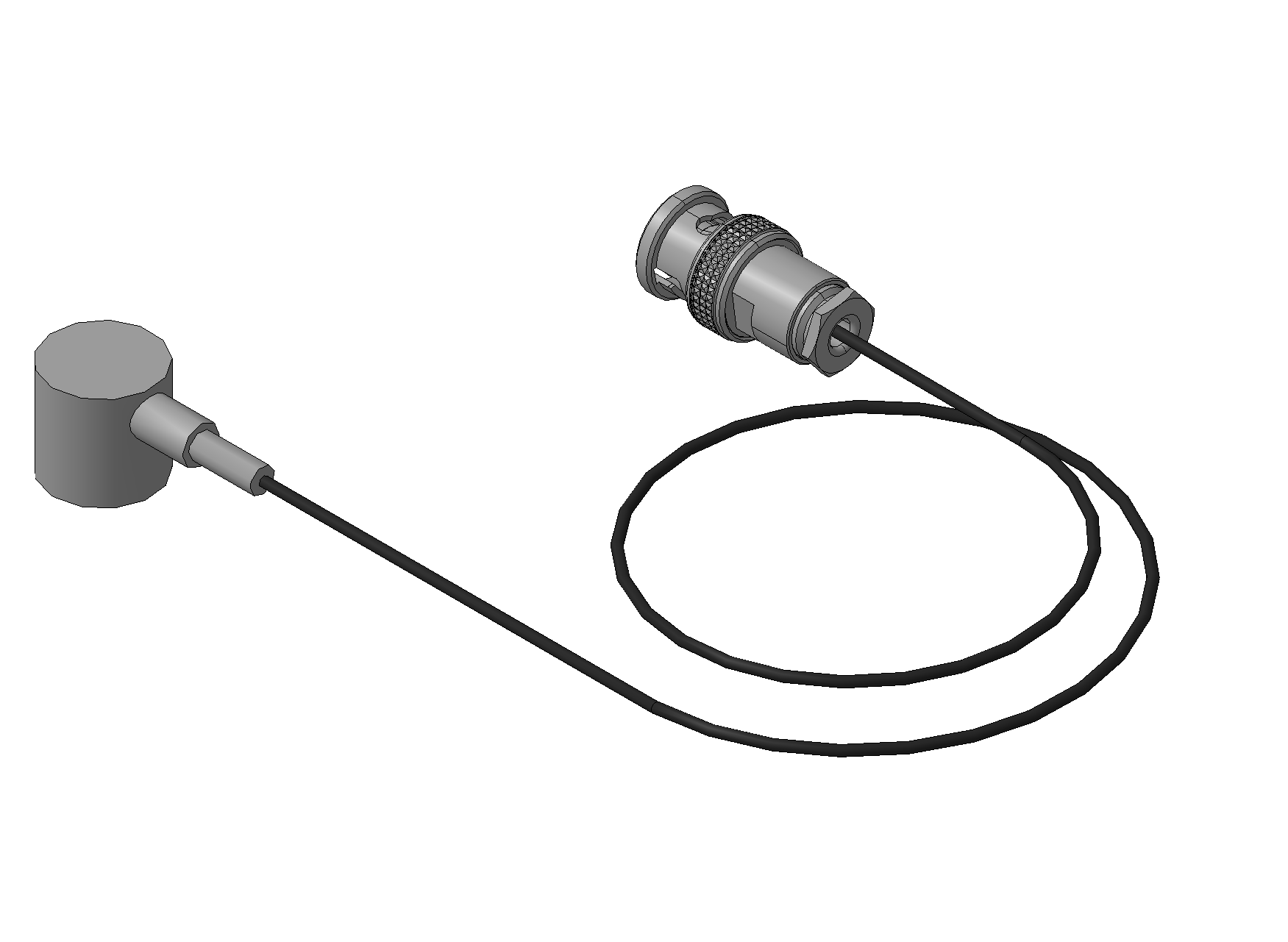

AE sensor

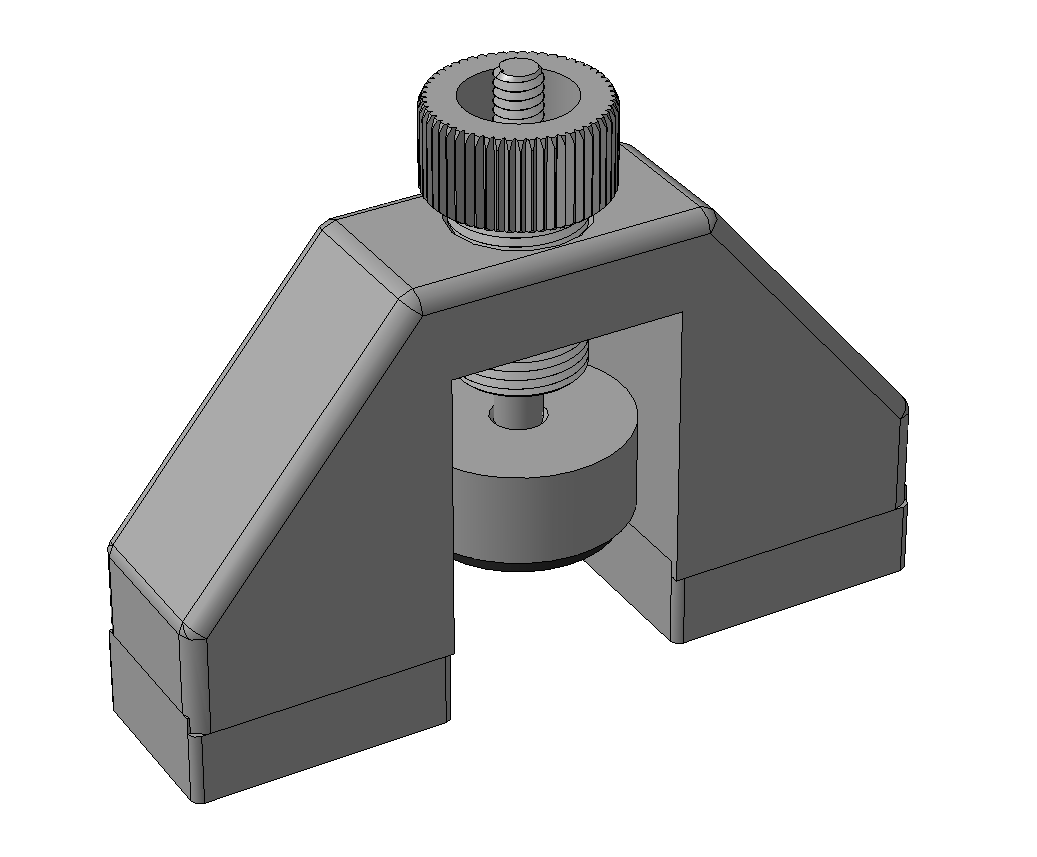

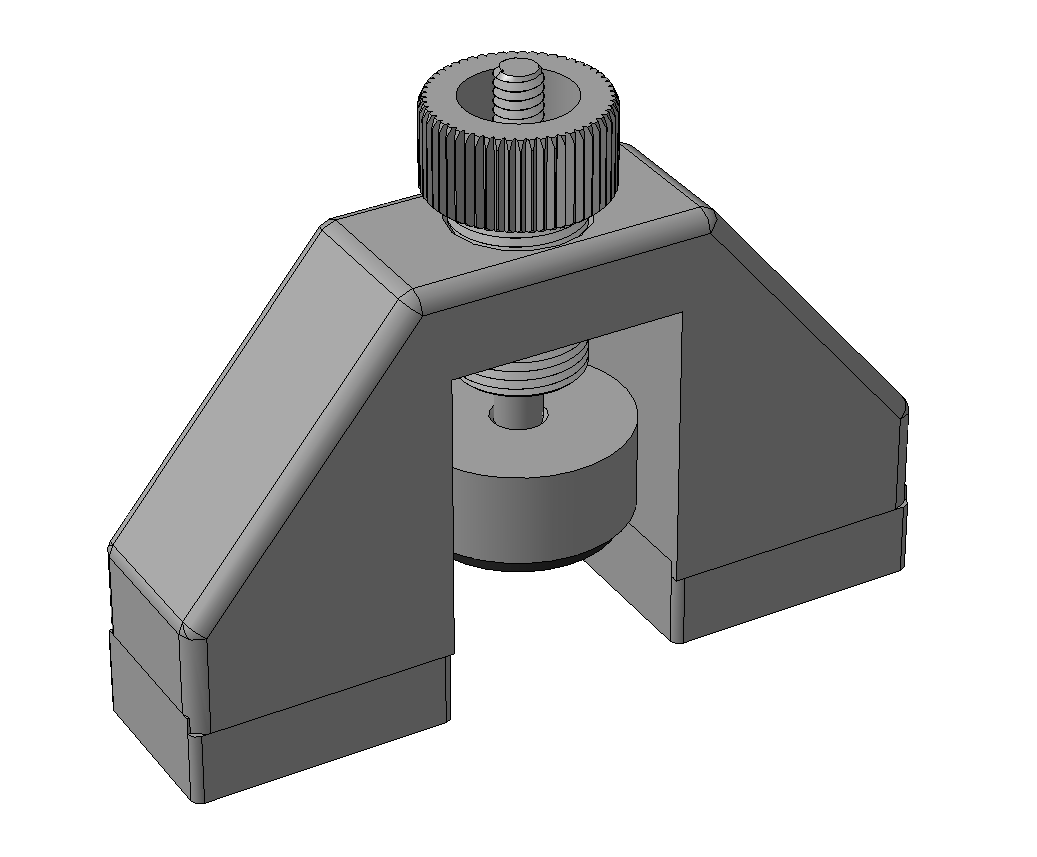

AE sensor magnetic holder

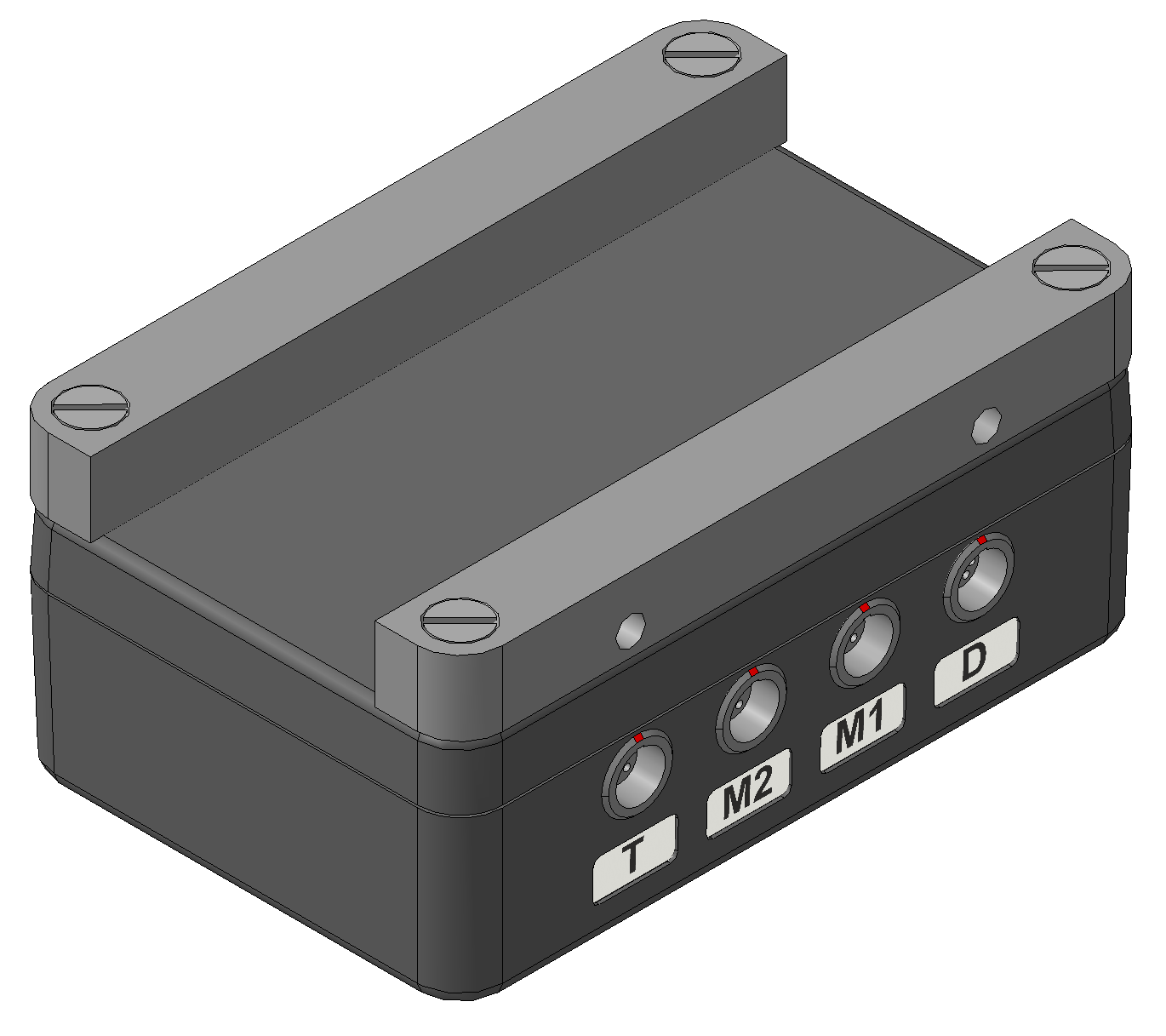

Measuring amplifier for strain gage transducers «MC3»

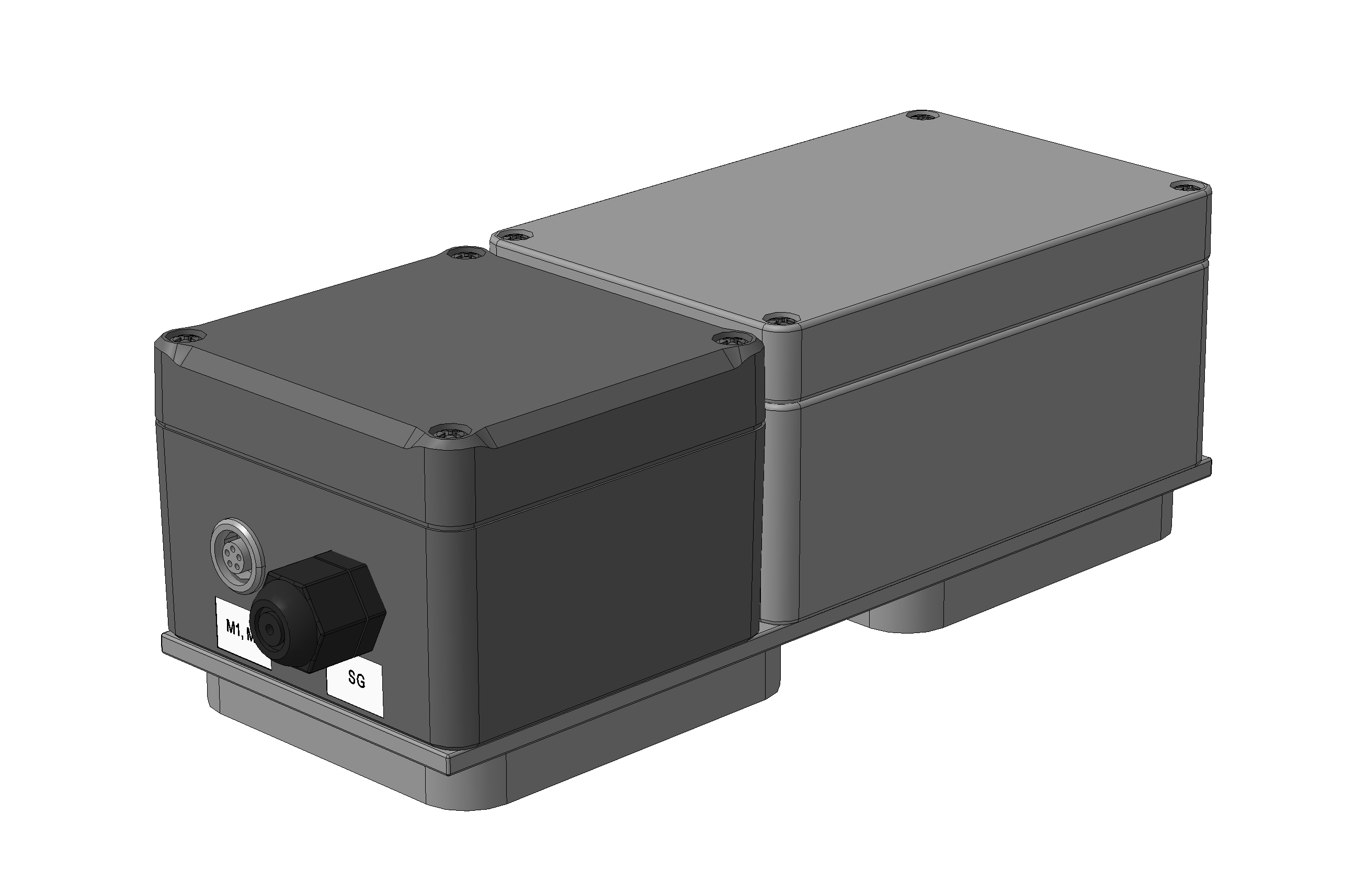

External matching unit «UNE-P»

Digital channel cable

Preamplifier cable

Parametric cable «MC3» -

Characteristics

Basic technical specifications

General parameters of the mainframe DisplayTFT LED, 5,7’’, 640х480 pixels, 262 144 colorsBattery endurance, hours8Supported interfaceSD/SDHC, Ethernet, USB2.0ProcessorARM9Software operating systemLinuxOperating temperature range, ˚С- 20 ÷ + 40Environmental protectionIP 65Overall dimensions, mm300х170х60Weight, kg2,6Analog channel to register AE and vibration Number of independence analog channels2Preamplifer supply voltage, V6Versions of switchable lengths of cable lines, m10 / 50Operating frequency range, kHz0,0005 ÷ 1000Versions of switchable frequency bands, kHz0,0005 ÷ 30, 1 ÷ 100, 30 ÷ 1000Possibility to load diferent digital flters+ADC resolution, bit16Maximum ADC sampling rate, MHz20Size of oscilloscope record bufer of each channel, Mb8Operation synchronism of analog channels, µs± 1Digital channel to connect external measurement blocks Number of independence digital channels2Transmitting interfaceRS 485Maximum baudrate, kBauds500External measurement block supply voltage, V5Operation synchronism of digital channels, ms± 1Operation synchronism of digital and analog channels, ms± 1External block for parametric measurements Number of universal measurement channels2Switchable operating modes for universal measurement channels:- current loop- voltage measurement, Vactive / passive± 1 / ± 10Measurement accuracy for universal channel0,2 % from measurement rangeOutput voltage to suppoly external sensors and devices, V12 / 24Variants of external connecting devices- pressure, displacement, inclination sensor;- tensometric amplifer.Number of temperature measurement channels1Measurement accuracy for temperature channel, ˚С± 0,5Supply voltage of the block, V5Maximum power consumption, W0,5Tensometric amplifer* Operating modes.«sensor» / «bridge»Resistance range for strain-gauges usage, Ω300 ÷ 1400Input signal range, V± 0,0004 / ± 4Output signal range

- voltage, V

- current, mA

± 5

4 ÷ 20* - MC3 tensometric amplifer characteristics are givenLeak detection mode Minimum detectable leak rate, l/min1Minimum diferential pressure, bar3Applicable valve inlet diameter, inch2 - 40Leak rate estimation error, %approx. 20Inspection time, miness than 15 -

Application

Shut-off valve leak detection method using «UNISCOPE» device

Purpose:

Among the main functions of «UNISCOPE» device there are revealing and quantitatively estimating the leakage rate in shut-off valves of various type and purpose, the operating pressure and diameter for liquid and gaseous operating fluid.The basic operational characteristic of any shut-off valve is the tightness. Tightness regarding outdoor environment prevents discharge of explosive, flammable and toxic materials into the atmosphere. At the same time, the valve internal tightness guarantees the accurate compliance with the operating procedures and helps to avoid any product losses while being delivered to the consumer.

In the leak detection mode the «UNISCOPE» device with high precision detects any faults of tightness within shut-off valve assembly, locates leak points and estimates gas or liquid loss volume:

- in shut-off valves of different types: gate, wedge, ball and disk shutter;

- in shut-off valves of underground or ground-based installations;

- for different media: natural gas, petroleum, water, etc.;

- in a wide range of boom drift diameter of 15 to 1400 mm (0.5 to 55 in).

Leakage detection method:

The detection method is based upon that fact that the gas or liquid leakage is accompanied by acoustic waves being spread within the tested object and registered by sensors that are mounted on the valve body. With the help of special data processing, the peculiar leaking signals are singled out. Their presence point out the occurrence of any leakage and their parameters define the leakage rate.

For the estimation of gas or liquid loss volume the empirical dependence is used. It has been obtained during the examination and testing of large number of shut-off valves. The determined dependence lets to take into account not only the type of shut-off valve, its size and operating conditions, but also different types of media as well.

Application:

Shut-off valve leakage detection method using «UNISCOPE» device is completely automated and does not require any additional training for operators. On the color device screen the general view of valve body is shown. The points to be measured are marked with indicators. With successive sensors reinstallation, the operator measures the acoustic noise within the testing points, the number of which can vary from 1 to 8, depending on valve type, size and geometry. It takes you no more than 15 minutes to complete the procedure. Once the data are acquired, they are automatically processed. The result of data processing is the tightness confirmation or the ascertainment of shut-off valve leakage and loss volume estimation.

Advantages:

Acoustic determination method and loss volume estimation are easy to use. They do not require any expensive pneumatic and hydraulic tests. All measurements are performed directly on the valve body without contacting flammable and explosive materials. The application of this method serves for the high performance testing. Using this method you can test and measure dozens of valves during a working shift.

The universal NDT instrument outlined below, named «UNISCOPE», is the company’s state-of-the-art design, intended to satisfy the highest requirements of NDT experts. At present, on the basis of a single hardware platform the instrument incorporates the two-channel AE system with advanced features, the acoustic leak detector, the tensometer and the vibrometer. Furthermore, additional functions of «UNISCOPE» are under development, which in the long view will allow for using this device as an ultrasonic thickness meter, a generator of test electric and elastic impulses, an integrated thickness meter, a measuring instrument of electrochemical potentials and terrestrial currents, an eddy-current scanner and a magnetometer. Such universality is reached through using various external measuring units to be connected to the common computing device, provided with generic software with the modern friendly interface.

For information visualization, the device is equipped with a display protected with a transparent plate from mechanical and climatic impacts. Battery charging (p. 3, fig. 2) and electric supply state (p.4, fig. 2) LED indicators are located on the face side of the device. The electric supply switch (p. 3, fig. 1), two connectors for sources of analog systems (p.4a, 4b fig. 1), two connectors for external digital blocks (p. 6a, 6b fig. 1), as well as the section of interface connectors protected with a plug (p. 5, fig.1) are located on the side of the device containing, in particular, a connector for storage batteries charging.

Fig. 1. Face panel (1 – panel of control push buttons; 2 –panel of adjustment push buttons; 3 – battery charging indicator; 4 – electric supply state indicator)

Fig. 2 General view of the device (1 – keyboard; 2 – display; 3 – ON/OFF push button; 4а – Channel No. 1 connector for registration of analog signals; 4b – Channel No. 2 connector for registration of analogue signals; 5 – plug of interface connectors section; 6а – digital channel No. 1 connector; 6b –digital channel No. 2 connector)

Distinctive peculiarities of «UNISCOPE»:

- small weight and optimal ergonomics for field operation;

- reliable protection from unfavourable external impacts;

- possible operation at negative temperatures;

- high modern level of hardware and software;

- two wide-band analog and two digital channels for connection of external measuring blocks;

- graphic image of results at the LCD display with light diode illumination;

- storage of big volumes of data at easily accessible information carriers;

- possible unification of two and more devices for multichannel measurements;

- prolonged operation from two built-in storage batteries.

Description of main operation modes

In the mode of AE measurements «UNISCOPE» is intended for nondestructive testing without decommission of industrial and technological pipelines, adapters and jumpers, gate valves and pressure regulators, vessels and cylinders, hoisting mechanisms and other industrial equipment along with possible linear localization and operative assessment of danger degree of AE sources.

Besides, in order to improve quality of useful signal separation at the background of various noises charge digital frequency filters and preliminary hardware filtration of input data by parameters of AE impulses are used. In parallel with AE registration by two analog channels parametric information can be recorded and by two digital channels in the single time scale for higher quality of the diagnostic information analysis.

In the leakage detection mode the «UNISCOPE» makes it possible to detect and quantitatively assess the values of gate valves leakages of various types and intention, working pressure and diameter for liquid and gaseous working environment. The leakage detection function is implemented on the basis of registration channels of AE impulses. The typical shape of leakage signals is identified by the system software. The value of medium consumption is evaluated on the basis of parameters of these signals. Depending on the type of the working medium, passage diameter and operating pressure of gate valves the average error of leakage may be equal from 0.1 to 20 l/min.

In the strain measurement mode the «UNISCOPE» is used for measuring the object nominal diameter in the real time scale. An important operation peculiarity in this mode is its possible use along with AE measurements for parametric testing accompaniment by means of observation of the changed value and loading character.

Unit «UNISCOPE» in Ex version and external matching unit «UNE-P» in Ex version have design implementing type of protection «n» (IEC 60079-15) and intrinsic safety «i» type for external circuits with level of protection «ia» (IEC 60079-11). Unit «UNISCOPE» in Ex version meets the requirements of IEC 60079-0. AE preamplifier «UNP» in Ex version is intrinsically safe (IEC 60079-11). Unit «UNISCOPE» in Ex version and connected devices can be located in hazardous areas according to their marking. Charger and interfaces connectors usage is forbidden in hazardous areas.

Explosion protection of AE preamplifier «UNP» in Ex version is provided by matching its intrinsically safe parameters with output intrinsically safe parameters of unit «UNISCOPE» in Ex version.

Accessories

|

Charger |

|

AE preamplifier «UNP» |

|

AE sensor |

|

AE sensor magnetic holder |

|

Measuring amplifier for strain gage transducers «MC3» |

|

External matching unit «UNE-P» |

|

Digital channel cable |

|

Preamplifier cable |

|

Parametric cable «MC3» |

Basic technical specifications

| General parameters of the mainframe | |||

|

Display |

TFT LED, 5,7’’, 640х480 pixels, 262 144 colors |

||

|

Battery endurance, hours |

8 |

||

|

Supported interface |

SD/SDHC, Ethernet, USB2.0 |

||

|

Processor |

ARM9 |

||

|

Software operating system |

Linux |

||

|

Operating temperature range, ˚С |

- 20 ÷ + 40 |

||

|

Environmental protection |

IP 65 |

||

|

Overall dimensions, mm |

300х170х60 |

||

|

Weight, kg |

2,6 |

||

| Analog channel to register AE and vibration | |||

|

Number of independence analog channels |

2 |

||

|

Preamplifer supply voltage, V |

6 |

||

|

Versions of switchable lengths of cable lines, m |

10 / 50 |

||

|

Operating frequency range, kHz |

0,0005 ÷ 1000 |

||

|

Versions of switchable frequency bands, kHz |

0,0005 ÷ 30, 1 ÷ 100, 30 ÷ 1000 |

||

|

Possibility to load diferent digital flters |

+ |

||

|

ADC resolution, bit |

16 |

||

|

Maximum ADC sampling rate, MHz |

20 |

||

|

Size of oscilloscope record bufer of each channel, Mb |

8 |

||

|

Operation synchronism of analog channels, µs |

± 1 |

||

| Digital channel to connect external measurement blocks | |||

|

Number of independence digital channels |

2 |

||

|

Transmitting interface |

RS 485 |

||

|

Maximum baudrate, kBauds |

500 |

||

|

External measurement block supply voltage, V |

5 |

||

|

Operation synchronism of digital channels, ms |

± 1 |

||

|

Operation synchronism of digital and analog channels, ms |

± 1 |

||

| External block for parametric measurements | |||

|

Number of universal measurement channels |

2 |

||

|

Switchable operating modes for universal measurement channels:

- current loop

- voltage measurement, V |

active / passive

± 1 / ± 10 |

||

|

Measurement accuracy for universal channel |

0,2 % from measurement range |

||

|

Output voltage to suppoly external sensors and devices, V |

12 / 24 |

||

|

Variants of external connecting devices |

- pressure, displacement, inclination sensor;

- tensometric amplifer. |

||

|

Number of temperature measurement channels |

1 |

||

|

Measurement accuracy for temperature channel, ˚С |

± 0,5 |

||

|

Supply voltage of the block, V |

5 |

||

|

Maximum power consumption, W |

0,5 |

||

| Tensometric amplifer* | |||

|

Operating modes. |

«sensor» / «bridge» |

||

|

Resistance range for strain-gauges usage, Ω |

300 ÷ 1400 |

||

|

Input signal range, V |

± 0,0004 / ± 4 |

||

|

Output signal range - voltage, V - current, mA |

± 5 4 ÷ 20 |

||

|

* - MC3 tensometric amplifer characteristics are given |

|||

| Leak detection mode | |||

|

Minimum detectable leak rate, l/min |

1 |

||

|

Minimum diferential pressure, bar |

3 |

||

|

Applicable valve inlet diameter, inch |

2 - 40 |

||

|

Leak rate estimation error, % |

approx. 20 |

||

|

Inspection time, min |

ess than 15 |

||

Shut-off valve leak detection method using «UNISCOPE» device

Purpose:

Among the main functions of «UNISCOPE» device there are revealing and quantitatively estimating the leakage rate in shut-off valves of various type and purpose, the operating pressure and diameter for liquid and gaseous operating fluid.

The basic operational characteristic of any shut-off valve is the tightness. Tightness regarding outdoor environment prevents discharge of explosive, flammable and toxic materials into the atmosphere. At the same time, the valve internal tightness guarantees the accurate compliance with the operating procedures and helps to avoid any product losses while being delivered to the consumer.

In the leak detection mode the «UNISCOPE» device with high precision detects any faults of tightness within shut-off valve assembly, locates leak points and estimates gas or liquid loss volume:

- in shut-off valves of different types: gate, wedge, ball and disk shutter;

- in shut-off valves of underground or ground-based installations;

- for different media: natural gas, petroleum, water, etc.;

- in a wide range of boom drift diameter of 15 to 1400 mm (0.5 to 55 in).

Leakage detection method:

The detection method is based upon that fact that the gas or liquid leakage is accompanied by acoustic waves being spread within the tested object and registered by sensors that are mounted on the valve body. With the help of special data processing, the peculiar leaking signals are singled out. Their presence point out the occurrence of any leakage and their parameters define the leakage rate.

For the estimation of gas or liquid loss volume the empirical dependence is used. It has been obtained during the examination and testing of large number of shut-off valves. The determined dependence lets to take into account not only the type of shut-off valve, its size and operating conditions, but also different types of media as well.

Application:

Shut-off valve leakage detection method using «UNISCOPE» device is completely automated and does not require any additional training for operators. On the color device screen the general view of valve body is shown. The points to be measured are marked with indicators. With successive sensors reinstallation, the operator measures the acoustic noise within the testing points, the number of which can vary from 1 to 8, depending on valve type, size and geometry. It takes you no more than 15 minutes to complete the procedure. Once the data are acquired, they are automatically processed. The result of data processing is the tightness confirmation or the ascertainment of shut-off valve leakage and loss volume estimation.

Advantages:

Acoustic determination method and loss volume estimation are easy to use. They do not require any expensive pneumatic and hydraulic tests. All measurements are performed directly on the valve body without contacting flammable and explosive materials. The application of this method serves for the high performance testing. Using this method you can test and measure dozens of valves during a working shift.